Industrial Process

Industrial Process

Our comprehensive portfolio of belt filters delivers a robust, highly consistent performance in your critical application. We can also create reliable solutions for your specific application needs by leveraging our material science capabilities. We provide unparalleled technical support, equipment versatility and dewatering expertise. Our adherence to internationally recognized manufacturing and quality principles assures consistent lot-to-lot performance and compliance with regulatory standards.

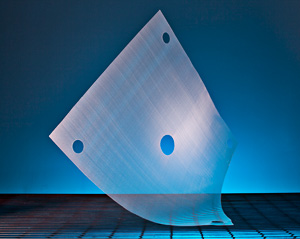

Technical Fabrics

Clear Edge Filtration technical screen fabrics provide the highest quality to meet your specific needs for screening, sifting, separating, filtering, straining and classifying. Our fabrics are designed to accommodate industry's diverse requirements, with nearly unlimited capabilities.

Belts - Woven/Spiral

When companies and machine manufacturers need high-quality machine belts, they count on Clear Edge Filtration to supply innovative products that meet a wide range of industrial and municipal needs. As a leading manufacturer of belting products, Clear Edge engineers its fabrics for excellent performance in a variety of process-critical applications for conveying, forming, pressing, processing and liquid filtration.

Filter Cloth

Clear Edge Filtration provides an extensive range of wet and dry filtration and screening products and fabrics to meet all your filter process needs. We have a deep knowledge of the many types of filter media, screening and sieving products, and decades of experience in manufacturing press cloths, bags and belts to suit practically any process equipment.

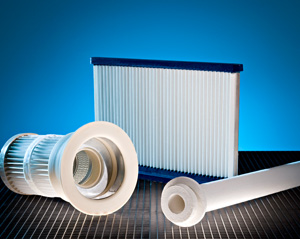

Dust Bags

Clear Edge Filtration offers the highest quality premium fabric filter bags – each specially developed to take advantage of unique treatments and advanced designs to ensure peak performance and reduce emissions. Whether you’re working in high-tech food and pharmaceutical environments or more industrial applications, our bags are specifically designed to withstand high temperatures and chemical attack.

Ceramics

Cerafil®, from Clear Edge, is a family of low-density ceramic filter elements used in filter plants for higher temperature applications. Extremely efficient and corrosion-resistant, Cerafil is the market’s leading brand of ceramic filter element and can be used in the most difficult gaseous conditions to help you meet increasingly stringent legislative requirements.